Underrated Ideas Of Tips About How To Build Compressed Air Engine

You will need to obtain the proper.

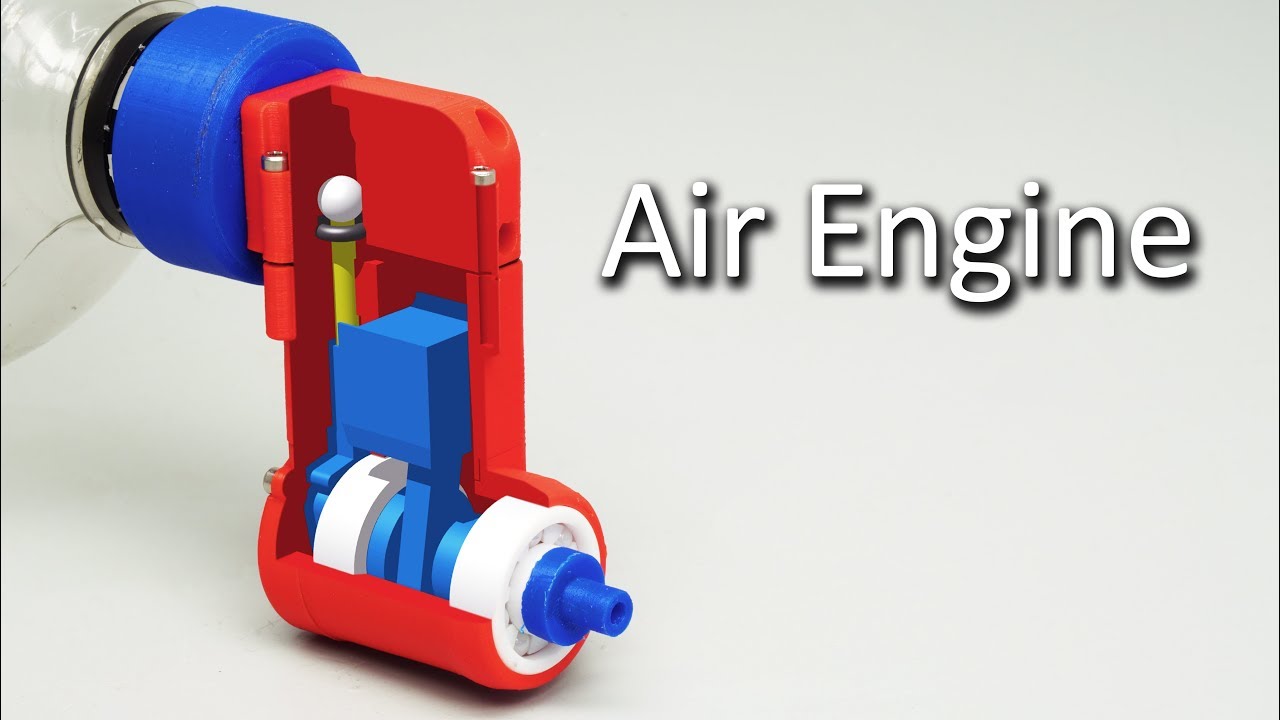

How to build compressed air engine. The compressed air car can only achieve speeds of about 35 mph, which is simply not fast enough for most consumers who need at least 60mph. Disabling one side of the v8 engine will basically make it into a 4 cylinder engine. The crank is the flat disc that holds the crankshaft and the dowel crank pin.

Steps to building a gas air compressor. The carburetor is not needed. The engine is easily converted to run on compressed air using air hose and solenoid switches, that fit directly into the spark plug holes.

Face the end to get it square then. Piston oil lubrication is the most common method of lubricating an air compressor. The gas tank is removed and thrown away!

The carburetor is not needed. The air is compressed by the compressor and then sent to the. In order for the compressed.

Making a simple compressed air engine from old motorcycle fork | diy machine idea Purchase an air tank and ensure it comes with a mounting plate. — take the measurement of the holes for the safety value and air input.

Compressor combination packages industrial duty air compressors for maintenance trucks, service fleets or technicians that need to save space and weight. Start by mounting the 2 piece of ø.63 in the three jaw chuck.